Connections to pipes

* dBL = drill-hole diameter

This information is only about connections that are made at a building site using a drill.

First, determine if the pipe type can be drilled. If it can, determine the location where drilling is permitted. Always follow the manufacturer’s specifications!

Connections to pipes

You must always use a core drill bit to make an opening for a connection. Using a hammer and chisel is not permitted.

You must always use a core drill bit to make an opening for a connection.

Using a core drill with a guide frame

New openings for connections must be made using a suitable core drill.

1 Drill motor (electric)

2 Handle

3 Water connection

4 Feed handwheel

5 Diamond core drill bit for concrete or stoneware

Core drill (for plastic pipes)

Connection area for circular profiles

The lateral drains connect with the public sewer at a height that is determined by structural aspects (profile type and diameter) and operational aspects.

The bottom 1 of the connection should be located between the widest point 2 and top 3 of the main sewer and should be higher than the water level during dry weather flow.

Ideally, the connection should be between 10 and 11 o’clock or between 1 and 2 o’clock.

This corresponds to an angle of ±45 degrees to the longitudinal axis of the pipe.

Connection area of main sewer

The same rules apply for pipes that are “egg-shaped” in cross-section.

For these pipes, too, the connection height should be between 9 and 3 o’clock.

Drilling – always towards the pipe’s centre!

The drill hole for the pipe connector must be made at a 90-degree angle to the longitudinal axis (i.e. towards the central axis) of the main sewer.

Drilling – always towards the pipe’s centre!

Corrosion protection

Note: For reinforced concrete pipes, it is necessary to protect any exposed steel against corrosion after the hole has been drilled.

It is preferable here to use suitable connector systems that offer structural protection for the steel reinforcement.

The connection can be made using moulded connectors or saddle connectors.

Connection using moulded connectors

Moulded connectors are components that are inserted into the round openings drilled into the pipe. They provide a tight seal. Installation details for moulded connectors can be found in the manufacturer’s instructions.

Connection using saddle connectors

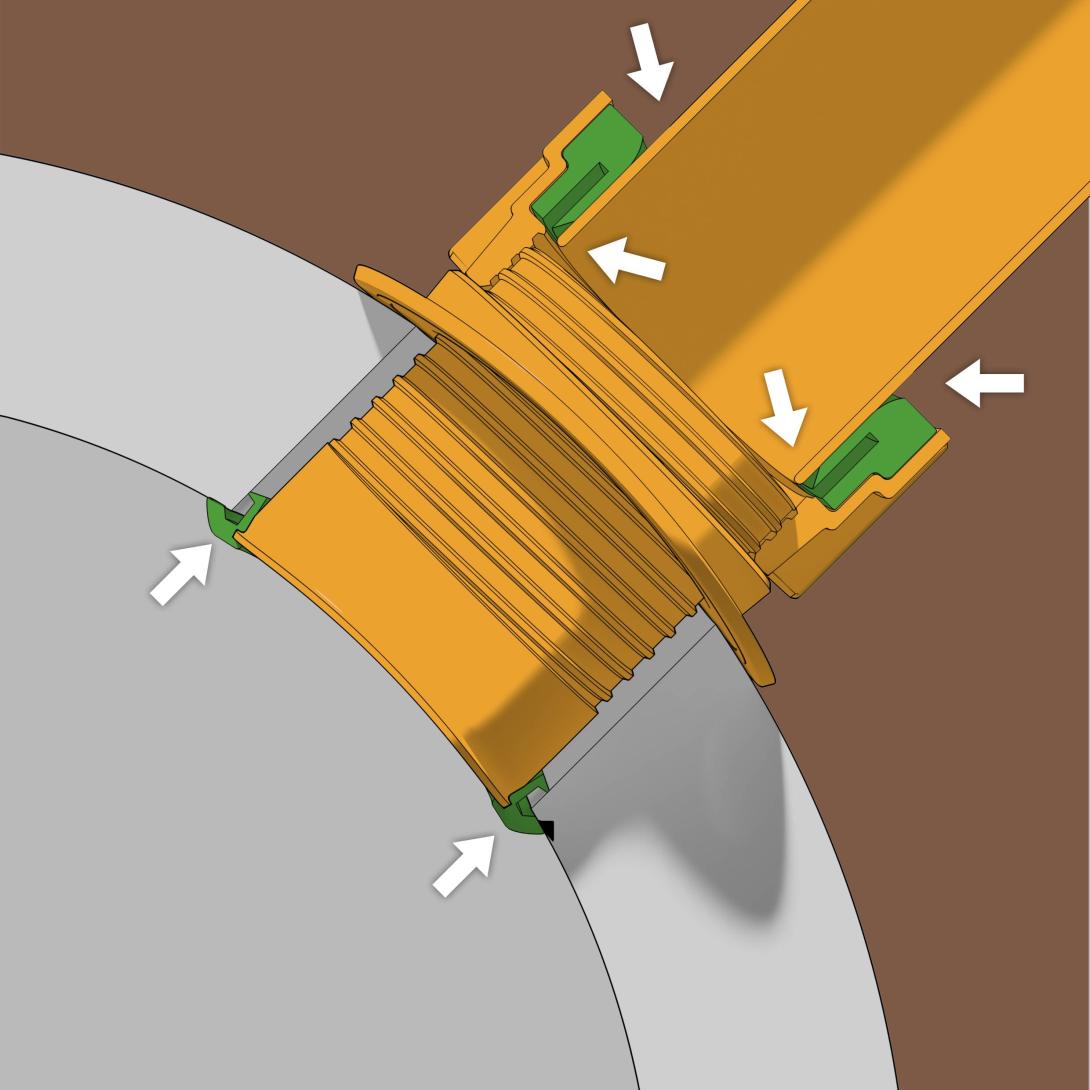

Saddle connectors are components that create a sealed connection between the external surface of the pipe and the internal surface of the saddle flange.

Installation details for saddle connectors can be found in the manufacturer’s instructions.

Connection using saddle connectors

The connecting pipe cannot extend past the inner surface of the main sewer pipe.

Compaction

Use extreme caution when compacting soil near connections. The backfill material must be carefully placed underneath the pipe by hand and compacted according to the foreperson’s instructions.

Flexible installation

Lateral drains must be configured and connected so that they can withstand movement. It is important to take into account possible subsidence and the resulting load on the connection area.